1000L Oil Tank

Product Detail

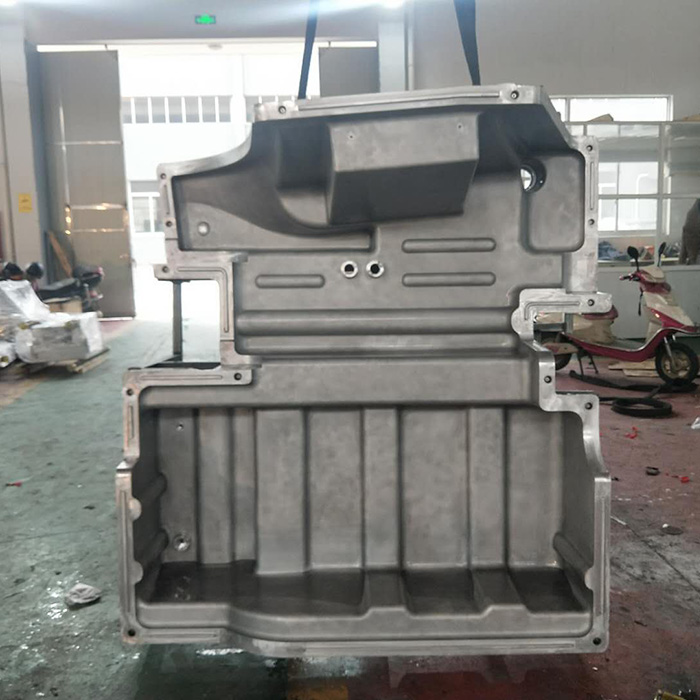

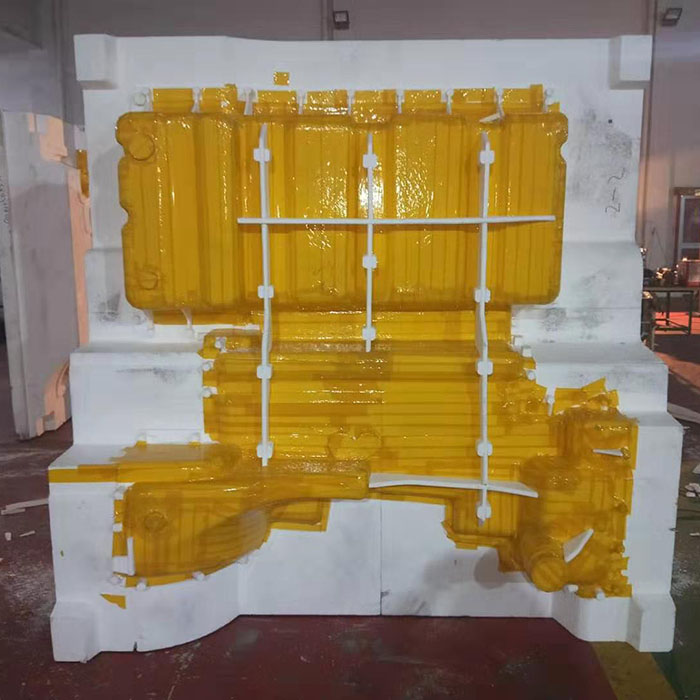

1: Rotational mold is made of wrought aluminium, casting aluminum which is easy heat conduction. The product is heated evenly which can reduce scrap rate during production.

2. The internal surface of the mold can be treated in various ways, such as shot blasting, mirror, teflon, rotten flowers, etc. It can meet the majority of customers’ mold requirements.

3. The wall thickness of the rotational mold is maintained to 10mm-11mm. In the production process, it can be heated quickly and cooled quickly which can save fuel cost, labor cost and time for manufacturers. It can also improve productivity greatly.

4. Our team has many years of accumulated experience and a complete set of facilities and solutions. We can help customers to identify problems and solve problems more accurate. Optimization of products, customer satisfaction is our highest purpose and glory.

5: Rotational mold is not easy to deformation, anti-aging, anti-corrosion, long life and so on after the process of heat treatment.

6. The Rotational mould adopts CNC machining technology to achieve high precision. Lay the best foundation for product production.

7: The products of roto mold are shaped by centrifugal force, and cooled at room temperature after heating by oven, which reduces the destruction of clinker atoms and perfectly retains the original characteristics of plastics.

8: The rotomolded products are widely used in various fields, such as thermal insulation box products, military transport box products, engineering sewage products. Agricultural machinery products. Coffee barrel products, playground products. Toy products, luminous furniture products, large bucket products, road anti - collision water horse products, water kayaking products. Recognized by more enterprises and groups.

9: Low cost: the same specification of rotational mold cost 80%-150% lower than injection mold.

10: The rotomolded products use one roto molding process. No return charge, high utilization rate of materials